What Does Laser Cutting Systems Mean?

What Does Laser Cutting Systems Mean?

Blog Article

In terms of modern production, the precision and efficiency of laser slicing technologies are really recreation-modifying. Laser chopping machines have revolutionized industries by providing a means of slicing supplies with unparalleled precision. Should you’ve ever marveled on the intricate models on steel or puzzled how complicated shapes are developed so seamlessly, it’s often the perform of an industrial laser cutting equipment.

Permit’s start with the basic principles: a laser cutter is often a Resource that utilizes a laser beam to chop materials. This beam is incredibly targeted and generates significant temperatures to soften or vaporize the material, creating specific cuts. Not like regular procedures, which might use mechanical blades, a laser cutter provides a amount of accuracy that is sort of unmatched. Picture trying to carve a delicate sample which has a hammer—Plainly, a laser cutter is lots a lot more refined!

Industrial laser slicing can take this technological innovation to the subsequent degree, delivering options for big-scale functions. These equipment are created to take care of significant supplies and substantial generation volumes, ensuring that even by far the most demanding projects are done with higher efficiency. Consider it since the distinction between using a precision knife for fragile paper crafts and a powerful noticed for chopping via thick Wooden.

Not known Factual Statements About Precision Laser Cutting

On this planet of CNC laser cutting, the “CNC” means Laptop Numerical Command. This technological innovation permits automated and highly specific cuts by pursuing digital designs. If you’ve ever used a pc to draw and after that viewed that drawing arrive at everyday living, CNC laser reducing is effective in the same way, translating electronic types into physical cuts. It’s like getting a virtual designer While using the precision of the laser.

On this planet of CNC laser cutting, the “CNC” means Laptop Numerical Command. This technological innovation permits automated and highly specific cuts by pursuing digital designs. If you’ve ever used a pc to draw and after that viewed that drawing arrive at everyday living, CNC laser reducing is effective in the same way, translating electronic types into physical cuts. It’s like getting a virtual designer While using the precision of the laser.The Of Sheet Metal Laser Cutter

Precision laser reducing is not almost building cuts; it’s about earning them proper each and every time. The laser can be modified to realize distinct depths and widths, making certain that every Minimize is exactly exactly where it has to be. This can be critical for apps where even a slight deviation could lead to important troubles. Think of it being a surgeon’s scalpel, in which precision is not just essential but absolutely vital.

Precision laser reducing is not almost building cuts; it’s about earning them proper each and every time. The laser can be modified to realize distinct depths and widths, making certain that every Minimize is exactly exactly where it has to be. This can be critical for apps where even a slight deviation could lead to important troubles. Think of it being a surgeon’s scalpel, in which precision is not just essential but absolutely vital.Laser chopping devices comes in numerous sorts, each customized to specific needs. Regardless of whether You will need a compact desktop design for hobby initiatives or a huge industrial equipment for manufacturing unit use, there’s a laser slicing solution out there for you personally. These devices range in electricity, velocity, and abilities, so it’s vital that you choose the right a person for your particular application.

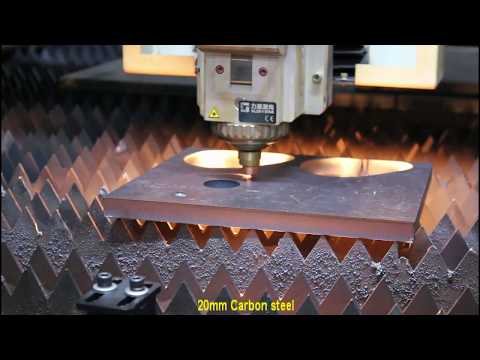

Sheet metallic laser cutters can be a Exclusive class of laser cutting equipment developed especially for slicing metallic sheets. They are commonly Employed in industries starting from automotive to aerospace because of their power to tackle steel with precision and pace. Photo a sheet of metallic just like a blank canvas, plus the laser cutter since the artist who produces complex and beautiful styles with remarkable accuracy.

Laser reducing providers are A different significant explore more aspect of this know-how. Not Every person desires to invest in their own individual laser reducing machine, particularly when they only will need occasional cuts or lack the space for this kind of products. Several businesses present laser chopping providers in which you can send your designs and have them Slice with significant precision. It’s like outsourcing your artwork to a talented Qualified.

Laser cutting programs integrate various components to provide the desired results. With the laser supply towards the cutting bed, and the Manage software package, each and every A part of the procedure operates alongside one another to make sure explore here a flawless operation. It’s a tiny bit like a symphony orchestra, the place Each individual musician has a specific position, and only by Doing work collectively do they make a harmonious overall performance.

With regards to laser chopping technology, the evolution has been rapid and impressive. In the beginning made use of mainly for cutting metals, these devices now manage a variety of materials which include plastics, Wooden, and even fabrics. This flexibility will make laser chopping technology a useful Software in a great number of industries. Imagine aquiring a Swiss Military knife that may take care of virtually any materials—This is often what modern laser slicing technological innovation provides.

The precision of laser chopping devices is really outstanding. They're able to Reduce components to inside of microns on the intended style and design, making certain that even quite possibly the most intricate facts are preserved. This degree of precision is particularly precious in industries the place correct measurements are critical. Think of it because the difference between a personalized go well with and off-the-rack outfits—the healthy is simply fantastic whenever.

All about Laser Cutting Technology

Yet another benefit of laser slicing know-how is its effectiveness. In contrast to traditional reducing methods That may require a number of actions or applications, laser slicing often completes the undertaking in a single go. This not merely quickens creation but in addition lessens substance waste. It’s like aquiring a substantial-speed coach that receives you on your destination speedily and successfully with no unneeded stops.During the context of industrial programs, the robustness of laser reducing equipment is important. These devices are developed to endure the demands of steady Procedure, often operating 24/7 in superior-volume configurations. Their sturdiness makes sure regular efficiency and trustworthiness, and that is important for maintaining creation schedules. It’s like aquiring a large-duty truck that reliably delivers goods day after day.

Among the impressive elements of laser chopping is its ability to develop clean up and exact edges. This lowers the need for post-processing, like sanding or finishing, which may be time-consuming and costly. The result is really a sleek, concluded product or service That usually calls for minimum extra function. Picture ending a craft job with no glue spills or tough edges—it’s that clear!